===

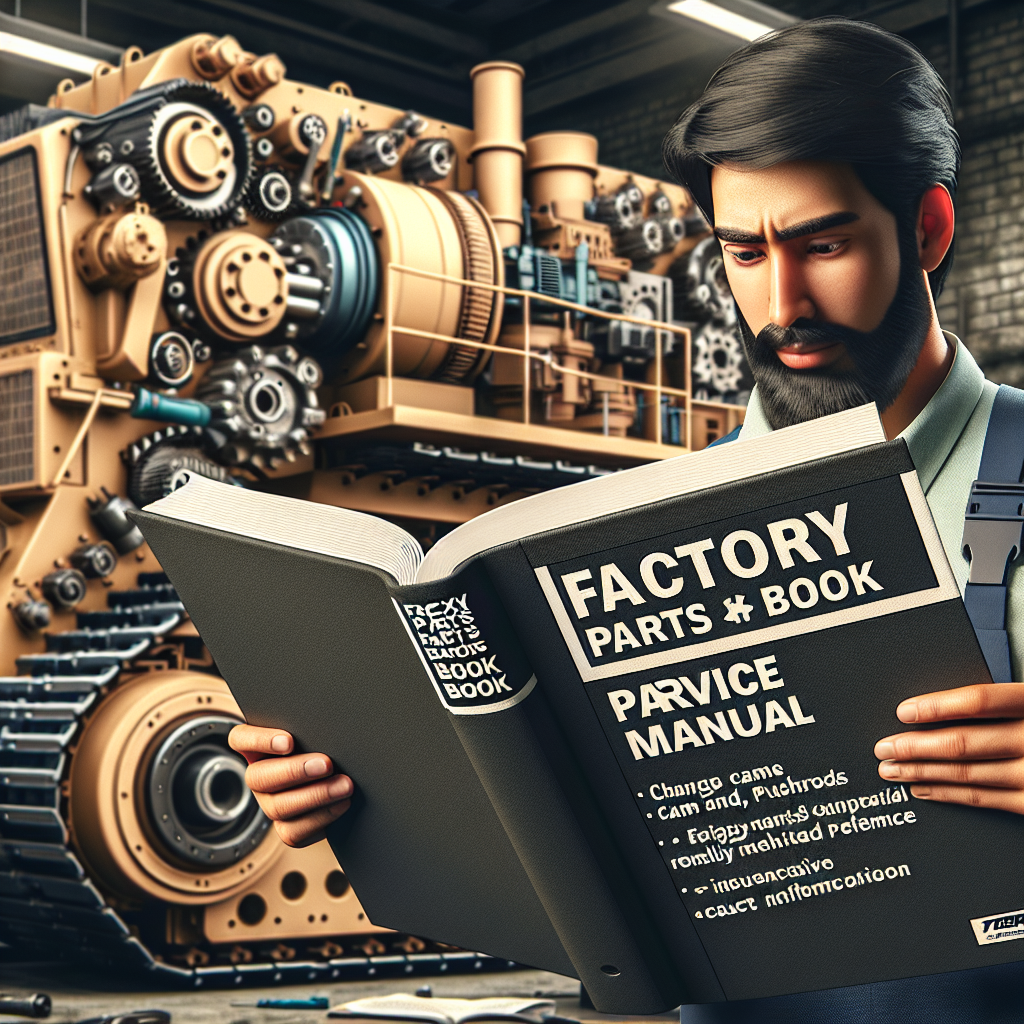

Service work is an essential aspect of maintaining and repairing machinery, ensuring its optimal performance and longevity. When it comes to complex tasks like changing cams and pushrods in Terex equipment, it is crucial to have access to accurate and reliable information. This is where the factory Terex parts book manual plays a vital role. In this article, we will explore the importance of using the factory Terex parts book manual for service work, the significance of changing cams and pushrods, how the manual enhances service efficiency, and the benefits of utilizing it for such tasks.

The Importance of Using Factory Terex Parts Book Manual for Service Work

When it comes to service work on Terex machinery, using the factory Terex parts book manual is of utmost importance. This manual is specifically designed by Terex engineers to provide comprehensive and detailed information about the equipment. It includes diagrams, specifications, and step-by-step instructions that are crucial for performing service tasks accurately. By relying on this manual, technicians can ensure that they are using the correct parts and following the recommended procedures, reducing the risk of errors and potential damage to the machinery.

To access the factory Terex parts book manual, one can visit the website https://terexmanual.com. This online platform offers a wide range of Terex manuals, including the parts book manual for various equipment models. Having access to this manual ensures that technicians have the most up-to-date information at their fingertips, enabling them to perform service work with precision and confidence.

Understanding the Significance of Changing Cams and Pushrods

Cams and pushrods play a crucial role in the operation of the engine in Terex machinery. The camshaft controls the opening and closing of the engine valves, while the pushrods transmit the motion from the camshaft to the valves. Over time, these components can wear out or become damaged, resulting in reduced engine performance or even failure. Therefore, changing cams and pushrods at regular intervals is essential for maintaining the efficiency and reliability of the machinery.

How the Factory Terex Parts Book Manual Enhances Service Efficiency

The factory Terex parts book manual significantly enhances service efficiency when it comes to changing cams and pushrods. With detailed instructions and diagrams, technicians can quickly locate the necessary components and understand the correct procedure for removal and installation. This eliminates guesswork and reduces the time required for service work. Additionally, the manual provides information on torque specifications, ensuring that the components are tightened to the appropriate level, preventing potential issues in the future.

Benefits of Utilizing the Factory Terex Parts Book Manual for Service Work

Utilizing the factory Terex parts book manual for service work offers numerous benefits. Firstly, it ensures that technicians have access to accurate and reliable information, minimizing the risk of errors and damage to the machinery. Secondly, the manual provides a comprehensive guide, enabling technicians to perform service tasks efficiently and effectively. Moreover, by following the recommended procedures and using genuine Terex parts, the manual helps maintain the warranty coverage of the equipment. Overall, utilizing the factory Terex parts book manual enhances service quality, prolongs the lifespan of the machinery, and maximizes its performance.

===

In conclusion, service work like changing cams and pushrods in Terex machinery requires the use of the factory Terex parts book manual. This manual provides vital information, ensuring that technicians can perform these tasks accurately and efficiently. By accessing the manual through platforms like https://terexmanual.com, technicians can rely on up-to-date information, diagrams, and step-by-step instructions, enhancing their service efficiency. By utilizing the factory Terex parts book manual, technicians can benefit from accurate information, efficient service work, and the preservation of warranty coverage.